How does a wood pellet machine work?

Generally, wood pellet machine can be classified into flat die pellet machine and ring die pellet machine.

Ring die pellet mill has large volume and high capacity. It is suitable for factory use and large-scale production. Flat die pellet mill is small and portable. It has lower capacity, suitable for home use and small-scale production. The price of flat die pellet mill is much lower than ring die pellet mill.

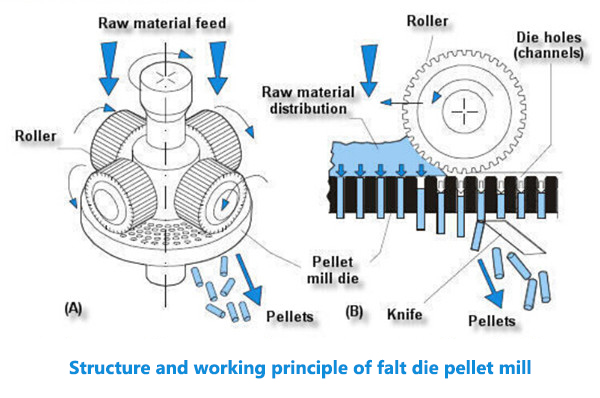

Structure of flat die pellet mill

From top to bottom, a flat die pellet mill is composed of a feed hopper, a upper cabinet, a discharge outlet, a spindle box, gear box, a transmission shaft, a electric control cabinet, an electric motor, a engine base, and 4 wheels, etc.

The electric motor can be replaced by a diesel engine, gasoline engine, or a PTO connector.

The core parts: roller and flat die

The pelletizing part of the flat die pellet machine is a press roller and a flat die. They are installed in the upper cabinet. There are 2-4 rollers installed on the 2 ends of the roller shaft. The rollers have grooves on the surface. The roller and flat die is made of superior alloy steel, whose hardness is 55-60 HRC.

There are many holes on the flat die, whose diameter is from 2.5mm to 10mm, and 6mm, 8mm and 10mm are the most common types. They realize the best compression ratio with a large number of experiments, suitable for more than 30 kinds of materials.

The clearance between the roller and flat die is 0.1-0.3mm. This is where the raw material layer forms. There are 2 adjusting nuts on the side of the pellet mill, you can adjust the clearance to adapt to different materials.

How does a flat die pellet machine work?

When you feed raw materials into the pellet machine through the hopper, they fall on the flat die and spread over it under the function of roller.

When you start the pellet machine, the electric motor runs and bring along the main shaft through the gearbox. The press roller is installed on the main shaft, so it rotates around the main shaft. Meanwhile, the rollers rotate around the roller shaft.

The rotating press forms strong pressure and press the raw materials into the holes on the flat die. The raw materials get molded in these holes. When they are squeezed out, they become solid cylinders. Meanwhile, the strong friction between roller and die heat up the raw materials to over 80°C, where the lignin and fibers get soft. They increase the adhesive force of materials.

The diameter of the pellets is determined by the hole size of the flat die, while the length is determined by the slicer under the flat die. When the biomass pellets come out in the shape of cylinders, the slicer under the flat die cut them into certain length. You can adjust the position of slicer to change the length.

After being cut by the slicers, the pellets fall down on the pellet-throwing tray. Under the function of centrifugal force, the pellets are sent out though the discharge outlet.

Two types of flat die pellet machine

Flat die pellet mill can be classified into roller-turned type and die-turned type. The former one has its flat die installed on the main shaft. When the machine works, the flat die rotates and the roller keep still. The later one has the press roller installed on the main shaft. The roller rotates with the main shaft, while the flat die keep still.

Roller-turned type adopts more efficient structure. It has larger capacity and more durable gearbox. But Die-turned type is more small and portable, with lower cost. Of course, both of them are able to make high-quality pellets.

Roller-turned pellet machine

Die-turned pellet machine

Advantages and weakness of flat die pellet machine

Flat die pellet mill has simple structure. It is small, light and portable. The cost is much lower than ring die pellet machine. It is easy to operate and maintain. You can observe the pelletizing process and solve any fault in time. So it is popular with farmers, home users, and small fuel production plant.

The flat dies are wearing parts, you need to replace it regularly. But it can be used with both sides. You can turn it over when one side has worn out. In this way you can extend their working life and reduce cost.

On the other hand, the moving distance are different in the inner and outer side of roller, which cause the slide of rollers and abrasion on the flat die. Currently, many flat die pellet machine adopt tapered roller to solve this problem. TICO flat die pellet machine adopts tapered roller and superior alloy steel in the flat die. Click the button below to get a quick quote!

Besides, the contact area of roller and flat die is smaller than ring die pellet machine, so the production capacity and forming rate is lower.

How does a ring die pellet machine work?

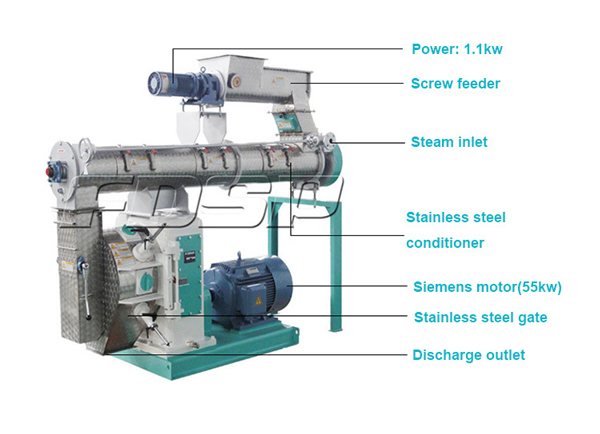

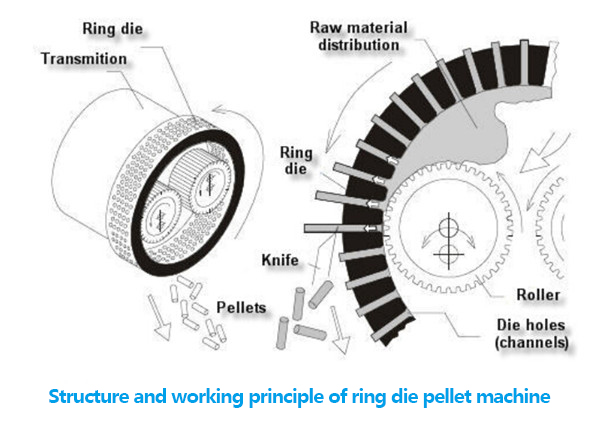

Structure of ring die pellet machine

A ring die pellet machine is composed of a screw feeder, conditioner, roller and ring die, discharge port, electric motor, gearbox, pedestal.

The ring die pellet machine is driven by a direct-connected motor. The motor connect with the gearbox through a shaft coupling. The gearbox bring along the main shaft, and the main shaft bring along the rollers. So the roller began to rotate inside the ring die.

When you feed raw materials into the ring die pellet machine through the hopper, they are transmitted to the conditioner, where the raw materials are mixed with vapor or butter. The conditioning of the raw materials aims to improve the adhesive force and forming rate.

Then, the processed raw materials will be transmitted to the pelletizing cabinet. Under the centrifugal force, they are distributed on the inner side of the ring die. The roller press the raw materials into the holes on the ring die. The high temperature and high pressure cause physical and chemical changes to the raw materials.

When they are squeezed out from the ring die, they become solid cylindrical sticks. The sticks grow longer, until they are cut by the slicer outside the ring die. Then the pellets fall down and come out through the outlet.

Two types of ring die pellet machine

According to different placements of the ring die, there are vertical ring die pellet machine and horizontal ring die pellet machine.

In the horizontal type, the ring die is placed vertically. When raw materials fall down from the conditioner, they are fed into the ring die horizontally by a forced feeder. In the vertical type, the ring die is placed horizontally. The feed hopper is right above the ring die, and the raw materials falls into the ring die directly.

In the vertical ring die pellet machine, both the roller and ring die rotate. They form centrifugal force and distribute raw materials uniformly. In the horizontal ring die pellet machine, only the ring die rotates. The raw materials are distributed in the ring die by the screw feeder.

Horizontal type

Vertical type

Advantages and weakness of ring die pellet machine

Ring die pellet mill features high capacity. The production per hour is from 800kg to 20t. As for flat die pellet machine, the capacity is from 100kg/h to 1t/t. So if you production requirement is under 800kg, you’d better choose flat die pellet machine, or ring die pellet machine is more suitable.

Due to the high production, the power consumption per unit is low. The abrasion between roller and die is smaller. The operation and maintenance is easy. The pellets are uniform in size.

On the other hand, the pressure between roller and ring die is lower than flat die pellet machine, and it takes more work to adjust the clearance. Ring die pellet machine cost much higher than flat die pellet machine. It has larger weight and large, and takes more place.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!