What is biomass gasification power generation?

What is biomass gasification?

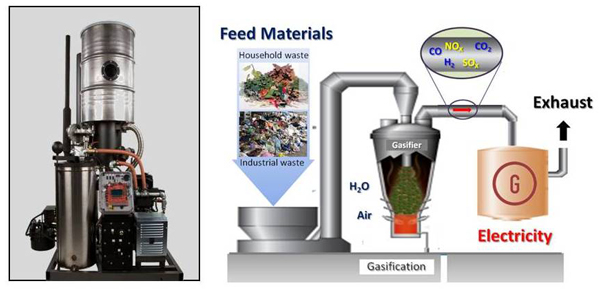

In brief, biomass gasification technology uses biomass as raw materials, oxygen, steam or hydrogen as agent, and turn the biomass into combustible gas through chemical reaction at high temperature. The combustible gas can be used in industrial and agriculture production, such as power generation, supplying heat, methanol and ethanol synthesis. Biomass gasification is a convenient way to make use of biomass, and take advantages of the cleanliness of the biofuel.

Biomass gasification power generation

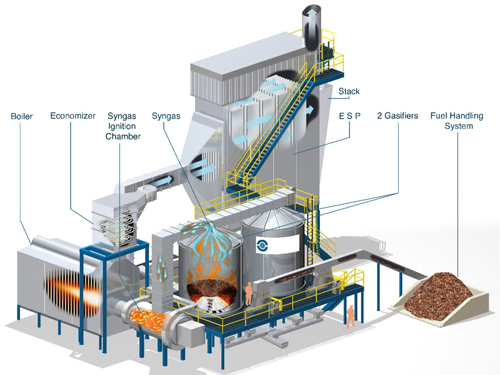

Biomass gasification power generation includes 3 processes. Biomass gasification is to transform biomass into gas fuel. Gas purification is to remove the impurities like ash, coke and tar in the gas with a purification system. Gas power generation is to burn the gas fuel in a gas turbine or a internal combustion engine. To improve the power generation efficiency, the biomass gasification power plant is equipped with a heat recovery boiler and a steam turbine.

Biomass gasification power generation

The process of biomass gasification

The raw materials for biomass gasification are various, including wood processing waste, agriculture residues. Such as sawdust, branch, crop straw, rice husk, corncob, etc. The material source is abundant and easy to obtain.

The gasification process is carried out in the gasifiers. The reaction process is complicated, which varies with the type of gasifier, the reaction condition, the features of raw materials, the grinding size. But they all contain the following processes.

The raw materials are burned in 4 layers: oxidation layer, reduction layer, thermal decomposition layer and drying layer. The reduction layer is the most important part that influence the quality and yield of the gas.

What is biomass gasifier?

The core equipment for biomass gasification is a gasifier, where the biomass is burned and gasified into combustible gas. The gasifiers can be classified into fixed bed gasifier and fluidized bed gasifier.

Fixed bed gasifier features simple structure, low investment, and easy operation. It has less requirement on the size and type of the raw material, but the gas production is small. Fixed bed gasifier is suitable for small gasification plant. Only up-flow type fixed bed gasifiers are suitable for large scale plant.

Fluidized bed gasifier has high heat transmission efficiency and high gasification intensity. It has high gas generation rate, suitable for large and middle scale production. It is a effective way to realize the cycle of biomass gasification—gas turbine generator—steam turbine generator. But it requires higher cost and complicated feeding process.

biomass gasifier

Features of biomass gasification power generation

Biomass gasification has become the most economical power generation method among all renewable energy technology. It's comprehensive cost has approached the level of power generation with conventional energy sources.

High flexibility

The gasified biomass can be applied in internal combustion engine, gas turbine, or combined with heat recovery boiler and steam boiler. You can choose a suitable one according to the scale of your power plant to achieve high power generation efficiency. The flexibility can meet the decentralized utilization of biomass energy.

High cleanliness

Biomass is a kind of renewable energy. It can reduce the emission of CO2, SO2 and other harmful gas. The gasification process is carried out at low temperature, so the NOX generation is low.

Cost-efficient

The flexibility of gasification power generation ensures the economic benefits in small scale production. The gas power generation process is simple, the equipment is compact, so it requires low investment than other renewable energy power generation.

Biomass gasification system

The history and current situation of biomass gasification

The biomass gasification technology has been more than 100 years. The first biomass gasifier appeared in 1883. It uses wood charcoal as raw material, and the fuel gas to drive the internal combustible engine in the automobile or agricultural machinery. The prosperous of biomass gasification is during the second world war, when all fuel oil is used in war and the domestic fuel is in short. Some countries developed car gasifiers that match with the automobile engine.

After the second war, owing to the exploration of oil in the middle-east area, most developed countries use oil as their main energy source. The biomass gasification technology has long stagnated. After the energy crisis in 1973, more and more countries realized the fossil fuel is non-renewable and not uniformly distributed. Biomass gasification regains the world’s attention as a mew energy technology.

With decades of development, biomass gasification technology has made great progress in Europe and America. Nowadays, the biomass gasifiers have achieved high atomicity and advanced technique. They are used for heat supply, power generation, and liquid fuel synthesis. Sweden, Denmark, Austria, Germany, America and Canada take the leading place in biomass gasification technology. They have achieves large-scale industrial operation.

Biomass gasification plant

The application prospect of biomass gasification

In terms of energy equivalent, biomass is the world’s 4th largest energy source after coal, oil and gas. Of the world’s total energy consumption, the biomass accounts for 14%, and even over 40% in developing countries.

Professors predict biomass energy will play an important part in the future. Nowadays, many countries take measures to adjust the energy portfolio, and give priority to development of biomass energy. In Europe, the biomass energy takes up 15% of the total energy consumption. It is predicted that biomass energy will take the place of 20% fossil fuel. More and more biomass plants will go into operation in Europe, America, Canada and Japan in the future.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!