Drum dryer

Drum dryers are used to dry biomass materials, such as wood chips, sawdust, wood shavings, wood chips, wheat straw, rice straw, corn stalks, bean stalks, potato vines, peanut vines, bamboo chips, etc.

Besides, it works well for many kinds of powdery materials. So, drum dryers are widely applied in fuel plant, fertilizer factory, chemical plant, medicine plant and other industries.

Specifications of the drum dryer

TICO drum dryer have 2 types, the production capacities are 0.7-1.5 t/h and 1.5-3.2 t/h. They can lower the moisture form 35%-50% to 12%-15%. After drying process, the raw materials are qualified for making biomass pellets.

| Model | Capacity (t/h) | motor power(kw) | Previous moisture | Final moisture | Overall size L*W*H(m) | Weight (kg) |

|---|---|---|---|---|---|---|

| GT1210 | 0.7-1.5 | 28 | 35%-50% | 12%-15% | 13*2.1*2.2 | 13500 |

| GT1615 | 1.5-3.2 | 45 | 35%-50% | 12%-15% | 20*3.2*4 | 19500 |

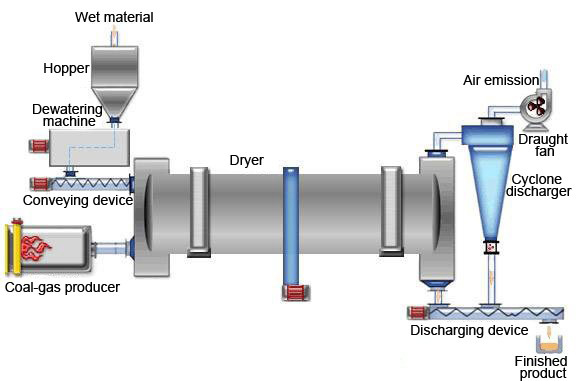

How does a drum dryer work?

The drum dryer is composed of a hot blast heater, a rotary drying cylinder, a lifting board, a support sealing device, a draught fan, a cyclone separator, and the transmission system.

After the raw materials are fed into the drum dryer by the conveying device, they go through the rotary drum with hot airflow by side. Within the drum, raw materials run along the spiral plate under the rotating force and the suction of the draught fan. There is a guide plate in the drum. Under the transmission and distribution of the hot airflow, the moisture in the wet materials get vaporized. Then they are expelled through the cyclone discharger.

Characteristics of biomass drum dryer

- Automatic control. It can ensure the drying process is constant and the drying effect is uniform.

- During the drying process, the stones and metals will be removed automatically, in case they enter the next procedure.

- The heat efficiency increases by 50%. Traditional single drum dryer has the heating efficiency of 35%, while this drum dryer reaches up to 70%.

- The rear transmission ensure the stableness of the drum dryer. It avoid the slip in the wheel rotation and improve the drying efficiency.

- Compared with traditional single-cylinder dryer, this drum dryer takes 50% less floor space, requires 50% less investment and save your power consumption.

- The conveyor can distribute the raw materials uniformly. It can adjust the drying time and ensure the drying effect.

- You can adjust the drying intensity to reach your required moisture content. You can also adjust the variable-frequency speed control system to change the materials flow rate.

- The temperature in air exhaust port is low. This ensures the continuous work of dust removal system.

- It can be matched with a hot blast heater to achieve high efficiency, thermal control, and simple operation. This equipment can reduce the power consumption by 20% and save the operation cost.

Rotary drum dryer in wood pellet plant

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!