Biomass pellet burner, wood pellet burning system

Biomass pellet burners can be applied in heating, cooking, drying and other fields by matching with boilers, furnaces or hot-blast stoves. A well-designed wood pellet burners can increase the burning efficiency of biomass pellets up to more than 86%. As biomass pellets have uniform size and density, they can realize automatic feeding and continuous burning.

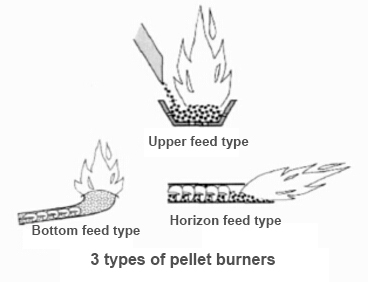

Classifications of biomass pellet burners

According to different feeding method, the pellet burners can be classified into 3 types: upper feed type, bottom feed type, and horizon feed type.

Upper feed type pellet burner

Upper feed type pellet burners are the most widely used in boilers and stoves. Most upper feed type burning device has blanking channel on the inner wall, which the pellet fuels pass through and get into the combustion chamber. The primary air and the warm air required for automatic ignition come in through the bottom of the combustion chamber. The secondary air come in through the holes on the wall of the combustion chamber.

Upper feed type pellet burner is usually equipped with a blower to provide combustion air and promote heat exchange between stoves and surrounding air. To facilitate ash removing, the grate is designed to be manual or automatic, so that the ash falls into the dust collector with the grate movement.

Bottom feed type pellet burner

Bottom feed type burners are originally used for the burning of wood chips, then they gradually become usable for biomass pellet fuel. The pellet fuels are fed to the combustion bed through the pipe at the bottom of the pellet burner by the feed conveyor. The primary air get into the combustion chamber through the holes on the feeding device or the combustion bed. And the secondary air get into the combustion chamber through the holes above the combustion bed. The bottom feed type pellet burner doesn’t need a separate dust collector. The ash after burning are squeezed into the dust collector or ash transmission system on the bottom.

Horizon feed type pellet burner

The working principle of horizon feed type pellet burner is the same with bottom type feed type. The only different is the shape of the combustion bed. Besides, horizon feed type pellet burner need additional dust collector.

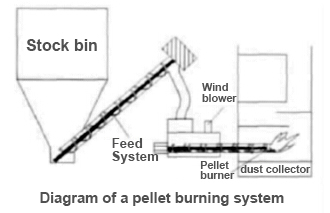

Feed conveyor in the pellet burning system

In most cases, the combustion burner is separated with the stock bin, so there should be a feed system between them. The feed system serves to feed the wood pellet fuel to the combustion chamber. The feeding speed is determined by the heat demand. The most common feeding methods are spiral conveyor and airflow conveying system.

Spiral conveyor

Spiral conveyor is the most common type of feeding device. It has simple structure, small volume and compact design. It is easy to operate and manage, with high safety and good sealing. It is suitable for short-distance conveying. The price is low but the power consumption is relatively high. It is sensitive to the metals, minerals and other impurities, so it requires the biomass pellet fuels are uniform, clean and under certain size.

Airflow conveying system

If the pellet burner has large distance with the stock bin, airflow conveying system is more suitable. The operation of airflow conveyor is similar with vacuum cleaner. Under strong suction of the pneumatic device, the wood pellets get into the combustion chamber through the pipe.

The airflow conveying system can realize long-distance and continuous conveying of small pellets and small-size block materials. It can realize horizontal and inclined conveying. The airflow conveyor features simple structure, good sealing, easy installation and maintenance. But the transmission speed is not uniform and constant, the exhaust noise is large, and the price is relatively high.

The operation and control of pellet burners

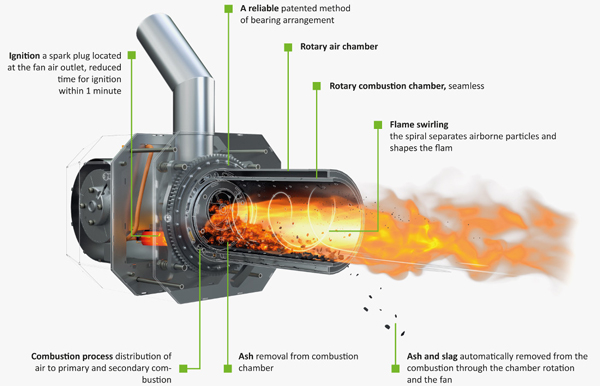

Ignition

Pellet burners adopt 2 ways of ignition: electronic ignition device and pilot flam. Electric ignition is more simple to control, with less pollutant emission than pilot flam.

Heat efficiency

To ensure the cleanliness of pellet burner, you should avoid multiple launching or using pilot flam, and ensure the combustion condition is stable. Well-designed pellet burner can achieve more than 90% efficiency at rated heat. Even under low load or unstable load, the heat efficiency is above 86%.

Combustion control

The pellet burner can adjust the feed quantity or combustion air volume to control the burning process. According to the heat demand, the pellet burner usually has several different output gears. When the output heat is lower than the set level, the pellet burner will run automatically until it achieves the set level.

The pellet burner is usually equipped with a temperature sensor to monitor the heat output. The combustion air is supplied by wind blower and monitored and controlled by a sensor. Small pellet burners adopts thermostat to control the heat output, while large burners adopts more complicated methods.

Running modes

Pellet burners has 2 main running modes. The first mode is represented by Sweden. The pellet burner is an independent unit. It usually matches with a standard boiler. The feeding, ignition and combustion are automatic. But the heat output is uncontrollable or only has 2 grades, full output and half output.

The other mode is represented by Austria. The feeding, ignition, burning and ash cleaning are automatic. The heat output can be adjusted within a certain range, for example, 30%-100%. It is easy to use, but the price is 50% higher than the first mode.

Ash removal device

The ash removing method of a wood pellet burner are mechanical scraping and mechanical vibration. Some pellet burners are equipped with ash compressor to ensure long time running. Well-designed pellet burner need little maintenance. Most ash removal device in pellet burners can meet the requirement of cleaning once a week.

Pollutant discharge

The smoke of biomass pellet burner mainly contains CxHy and CO. They are generated by the insufficient combustion of wood pellets, affected by the composition of the wood pellets. The smoke from pellet burner is little, especially those with inlet and exhaust devices. As the nitrogen and sulfur content in the biomass pellet fuel is low, so the NOx and Sox emission is far lower than coal.

Problems of biomass pellet burner

The technology of pellet burner is getting mature with the increasing application of biomass pellet fuel. But currently, the wood pellet burner still have some problems: the varieties are not wide, the application areas are restricted.

High ash deposition and slagging rate

The Si content is high in straw materials. The deformation temperature of straw ash is usually 750~1000℃, so the ash deposition speed is higher than wood pellets.

Ash removal is an problem that cannot be ignored in biomass pellet burner. The ash deposit usually contains large quantities of alkaline components and chloride. The scale and slag will not only influence the heat efficiency of the burner, but also endanger the safety of burning equipment.

According to research, the potassium, chloride and sulfur elements has great effect on slagging. The slagging rate increase along with the temperature, the size of hearth, and the thickness of fuels.

Chlorine corrosion

Straw pellets contains high alkali metal and chlorine content. In combustion process, almost all the chlorines have evaporate. They turn into HCL, CL2 and alkali chloride. As the smoke get cooled, the alkali chloride congeal on the surface of heat exchanger. They have reaction and generate sulfate and chloride, which has strong oxidizing capacity. They can speed up the corrosion of metals, and lower the heat transfer efficiency. In this regard, straw pellets has more damage to the pellet burner than wood pellets. In other words, straw pellets has higher requirement on the burning device.

Low degree of automation

Up to now, a large portion of pellet burners still adopt manual feeding and half-automatic feeding system. The low degree of automation hinders the large-scale application of wood pellet fuel.

Many small pellet burners ventilate naturally, so they usually have the problems of insufficient combustion and high pollutant emission.

Conclusion

Biomass pellet burners have been widely applied in heat supply, biomass boiler and biomass power generation. Well-designed pellet burner can increase the heating efficiency, reduce slag and pollutant emission, and save labor work. With the increasing application of biomass energy, it has higher requirement on the pellet burning technology.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!