Why is biomass a better alternative to natural gas?

Competition between biomass fuel and natural gas

In recent years, the application of biomass fuel is increasing. In many places, there arise competitions between biomass fuels and natural gas. In this passage, I will take boiler burning for instance, and compare the equipment cost, operation cost and environment effect of biomass boiler and natural gas boiler.

This blog compares the economic and environmental effect of biomass fuel and natural gas. The equipment cost of biomass boiler is higher than that of natural gas boiler. Considering the high price of natural gas, the annual operating cost (including the cost of fuel, electricity, labors and maintenance)of natural gas is higher than biomass boiler.

When using biomass fuels, it requires to be equipped with dust collector, sulfur and nitrate removing device to ensure the pollutant emission meet the standard. As for natural gas boiler, it adopts low-nitrogen combustion technology or denitrification device to ensure the NOx emission meet the standard.

Analysis of biomass energy

Biomass energy is solar power deposited in biomass materials in the form of chemical energy. It comes from the photosynthesis of green plants. It has the form of solid, liquid and gas. Biomass energy is known as a renewable energy.

According to the different sources, the biomass fuels can be classified into 6 kinds: crop straw, forestry waste, animal dung, aquatic plants, energy plants, life garbage.

Biomass energy has the following advantages

Low cost, wide distribution, large volume, renewability, storable, easy to use.

Biomass energy also has some disadvantages:

- Low energy density, not suitable for long-distance transportation. To ensure the biomass fuel supply, it requires large room for storage, which brings management problem.

- Crop straw has wide distribution, but it is affected by regions, seasons, weathers and other factors. The supply is not stable. Besides, the calorific value varies a lot. Some are not suitable for boilers.

- Different kinds of biomass fuels have different combustion effects, which may cause slagging and leaves too much ash. The alkaline content in the ash will hinder the continuous work of biomass boiler and cause corrosion.

- Biomass fuels are easy to get damp. The moisture content have great effect on the combustion temperature. Over-high moisture content will make the biomass fuel unable to burn.

Economical effect

Equipment cost

Take a 4t/h steam boiler for example. The mainframe of a DZL horizontal biomass boiler costs around ¥180,000, the cost of auxiliary machinery and installation is around ¥65,000, so the total equipment cost is ¥245,000.

A WNS series natural gas boiler costs around ¥150,000, the cost of auxiliary machinery and installation is ¥55,000, so the total equipment cost is ¥205,000. Therefore, the equipment cost of biomass boiler is higher than that of natural gas boiler.

Annual operating cost

We still take a 4t/h steam boiler for example, and compare the annual operation cost of biomass fuels and natural gas boilers. The operation cost of a boiler includes fuels cost, electricity consumption, labor cost and maintenance cost.

Biomass boiler

Annual fuel cost

- For example:

- The heat efficiency of a biomass boiler is 80%

- The calorific value of biomass fuel is 17.58MJ/kg at least

- The cost of wood pellets is ¥1250/t

- A biomass boiler consume 717kg wood pellet per hour

- The boiler runs for 10 hours everyday

- The annual running time is 300days

- By calculation, the annual fuel cost is ¥2,688,800

Annual electric charge

- For example:

- The total power of a force and induce draft fun is 29.5kw.

- The total power of the reduction box, feeder, water pump and conveyor is 10kw.

- Then the total power of the biomass boiler is 39.5kw.

- The electricity price is ¥1.0/kwh,

- The daily running time is 10 hours

- The annual running days are 300 days

- Then the electric charge for a year is ¥118,500

Annual labor cost

- For example:

- The work has two shifts a day.

- Each shifts need 2 person. A fireman and a water operator.

- The salary is ¥3000 per person.

- The labor cost is 144,000 per year.

Annual maintenance cost

Biomass boiler usually has many auxiliary machinery. Their failure rate is higher than gas boiler. The annual maintenance cost is in proportion to the equipment cost. If the maintenance cost is 2.5% of the equipment cost, then it is ¥6100 annually.

By calculation, the annual running cost of biomass boiler is ¥2,957,400.

Natural gas boiler

Annual fuel cost

- For example

- The heat efficiency of biomass boiler is 90%.

- The calorific value of natural gas is 35.58MJ/kg.

- The price of natural gas is ¥3.1/m3.

- A gas boiler can consume 315m3 natural gas every hour.

- A gas boiler operates 10 hours everyday, 300 days every year.

- By calculation, the annual fuel cost is ¥2,929,500.

Annual electric charge

- The power of the burner is 7.5kw.

- The power of water pump and other power utilization equipment is 7kw.

- So the total electric power of the biomass boiler is 14.5kw.

- The electricity price is ¥1.0/kwh.

- The working time is 10 hours every day, 300 days every year.

- So the annual electricity cost is ¥43500.

Annual labor cost

- The work has 2 shifts a day.

- As the gas boiler has higher automation, and the operation is simple, it requires only 1 fireman.

- The salary is ¥3000 per month, so the annual labor cost is ¥72000.

Annual maintenance cost

- The maintenance work of a gas boiler is not much, the cost is low.

- Suppose the maintenance cost is 1% of the equipment cost, then it is ¥2100 every year.

By calculation, the annual running cost of a biomass boiler is ¥3,047,100.

Conclusion

In terms of the equipment cost, biomass boiler is higher than natural gas boiler. In terms of the annual running cost, as natural gas boiler has higher automation degree, requires less power consumption device, and less maintenance, the electric charge, labor cost and maintenance cost is lower than that of biomass boiler. But considering the high price of natural gas, the total operation cost of natural gas boiler is higher than that of biomass boiler.

Environmental effect

Biomass fuel

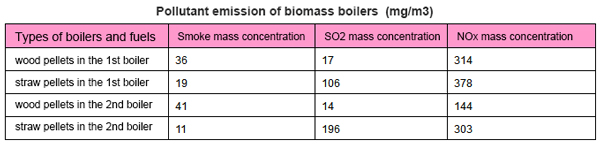

Researchers measured the emission of smoke, SO2 and NOx in 2 biomass boiler.

These 2 boilers has similar evaporation capacity. Both of them are not equipped with sulfur and nitrate removing device. But the first one is equipped with a bag-type dust collector, and the second one is equipped with a film-type dust collector.

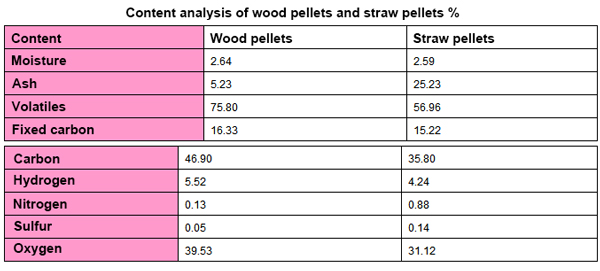

The biomass fuels are wood pellets and straw pellets. Their element and composition are the following.

The pollutant emission of biomass boiler is displayed in the chart below. According to the stipulated standard, the smoke, SO2 and NOX emission should be lower than 20mg/m3, 50mg/m3, and 200mg/m3.

As the chart shows, the boiler equipped with film-type dust collector can reduce the ash emission effectively. In terms of SO2 emission, the wood pellets can meet the stipulated standard even without sulfur removing device. As for NOx emission, the wood pellets can meet the standard in boilers equipped with film-type dust collector.

Natural gas

Natural gas is a high quality and clean gas fuel. The adoption of natural gas in the boiler can reduce the air pollution remarkably. The ash, sulfur and nitrogen content in the natural gas is low. The smoke of natural gas contains little SOx, which an meet stipulated standard. But the NOx emission is still a problem. Researched found the NOx emission of natural gas boiler is 125mg/m3, and 25% of them is more than 150mg/m3.

Conclusion

According to the analysis above, the type of biomass fuel has great influence on the pollutant emission. Wood pellets has less SO2 emission than straw pellets. The biomass boiler with film-type dust collector has better ash removing effect than bag-type dust collector.

The NOx emission is beyond standard in biomass boilers without sulfur or nitrate removing device, whatever wood pellets or straw pellets. Therefore, it is recommend to equip effective dust collector, and sulfur and nitrate removing device.

Natural gas has advantages in cutting smoke and SO2 emission. But with the increasing emission standard, more natural gas boilers will adopt low-nitrogen combustion technology and nitrate removing device.

The respective advantages of natural gas and biomass fuel

The price of biomass boiler is higher than natural gas. Their operating cost is similar considering the rise of natural gas price. Besides, the natural gas boiler is easier to control, and it doesn’t take much floor space or fuel storage room.

The price of natural gas is under government control, so it won't fluctuate sharply. The natural gas supply can be guaranteed when the gas boiler is in use. Biomass pellets supply is restricted by seasons. The price and supply is unstable, which usually takes up large warehouse space.

In terms of environmental protection, biomass boilers have to be equipped with dust collector, sulfur and nitrate removing device to ensure the smoke, SO2 and NOx emission meet the standard. But natural gas boilers doesn’t need dust collector or desulfurizer, but it need to adopt low-nitrogen combustion technology or nitrate removing device to cut the NOx emission. Besides, the natural gas boiler doesn’t need dust cleaning process.

On the other side, biomass fuel is renewable. It is solar energy deposited in plants by photosynthesis. As statistics show, the biomass energy generated by photosynthesis is 173 billion ton, but only 3% of them are utilized. Besides, biomass energy is carbon neutral, which means the CO2 consumption in its growth equals the emission in biomass fuel burning.

Fluidized-bed combustion is a technology based on gas-solid fluidized state. It has good adaptability to biomass fuels, the pollutant gas emission is low. By adding desulfurizer to the fluidized bed, it can remove the sulfur directly, and reduce the SO2 content in the smoke sharply.

Nowadays, the fluidized bed can be used for the combustion of different kinds of fuels, suitable for the co-firing of biomass and coals. The type of fuels and their proportion is adjustable, so you can choose them according the price to lower your cost.

The high price of natural gas is a problem. And the price disparity between summer and winter is getting serious. Biomass is an excellent substitute for traditional fuels. To meet the environmental requirement and achieve higher economical benefits, it is important to improve the application technology of biomass fuel, and increase the proportion of biomass in energy mix.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!