Convenient and flexible mini pellet machine for sale

Mini pellet machine features small size, light weight, and high portability. It is suitable for home use, small scale production, raw material testing, and training before building a pellet plant.

TICO mini pellet machine refers to the ZLSP150 type. It is a flat die pellet machine, driven by a 3phase 5.5kw electric motor or a 8HP diesel engine. The net weight is 95kg. The size of a mini pellet machine is as small as 800*450*700. The following are the specifications of TICO mini pellet machine.

| Model Number | Power | Output(kg/h) | N.W./G.W.(kg) | Package Size(mm) |

|---|---|---|---|---|

| ZLSP150B |

electric motor 3phase, 5.5Kw |

50-100 | 95/100 | 800*450*700 |

| ZLSP150A |

diesel engine 8HP |

180/220 | 1000*500*750 |

Mini pellet machine is able to process various biomass materials, like sawdust, wood shaving, crop straw, rice husk, grass, alfalfa, etc. The wood pellet production capacity is 50-100kg/h. The mini pellet machines are equipped with wheels that makes them movable and flexible.

How to install the mini pellet mill?

After you ordered the mini pellet mill from TICO and complete the payment, the product will be delivered after 7-15 days. When you receive the mini pellet mill, it is encased in a wooden box, with a hopper, 4 wheels, installation tools, and the instruction book in it. You only need to install the hopper at the top of the pellet machine, and install 4 whiles at the base with tools. Then, you can operate it according to the steps in the instruction book.

How does the mini pellet mill work?

The raw materials for making wood pellets should have the moisture content of 14-20% and the size under 5-6mm. If the raw materials cannot meet the standard, it need treatment ahead of time. We offer hammer mills to reduce the size of biomass materials, and airflow dryer to lower the moisture content.

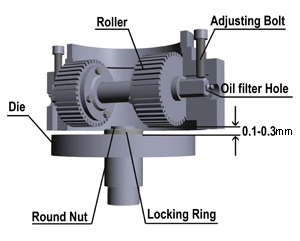

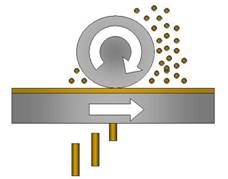

After pre-treatment, the raw materials are fed to the mini pellet machine though the hopper. In the compression chamber, the roller rotates and presses the raw materials to the holes on the flat die. The biomass materials are formed into solid cylindrical pellets in the pellet mill die. Under the flat die, a slicer cut off the pellets.

Features of TICO mini pellet machine

- The mini pellet mill adopt flat die design. The production capacity is not as high as ring die pellet machine. But it enable easy access to the pellet die compression chamber for cleaning and maintenance. Users can dispatch it quickly by unscrewing the bolt.

- The mini pellet machine can also produce feed pellets for cattle, fish, cat, sheep, etc. We can provide flat dies with the hole sizes of 2.5-8mm to produce animal feeds of different sizes. What’s more, mini pellet machines can also produce animal beddings for pets.

- TICO mini pellet mill is ISO and CE certificated. The roller and flat die are cast from superior alloy steel and processed by vacuum heat treatment. Before delivery, we carries out routine test and random inspection to ensure the quality. We also provide 1 year warranty and life-long after-sale service.

If you want to get the specific price or more details of the mini pellet machine, please contact us in the form below. Our customer services will reply you within 24 hours.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!